SEAT UPHOLSTERY

by Yuya Zhou / in MATERIAL & TECHNIQUE RELATED / on 01/30/2022

This is an upholstered seat I made recently. I will introduce the making process as detailed as possible.

Before you start, make sure the wood frame is sanded already. Try to avoid all sharp edges and corners! Because the sharpness might damage the foam.

Material list:

- a wood frame

- a roll of elastic band

- 2 inch thick foam (medium density)

- 1 inch thick polyester batting

- muslin

- a piece of fabric you like

Tool list:

- electric foam cutter

- fabric scissors

- staple gun & staples

- webbing stretcher

Step one: Staple the elastic band to the wood frame

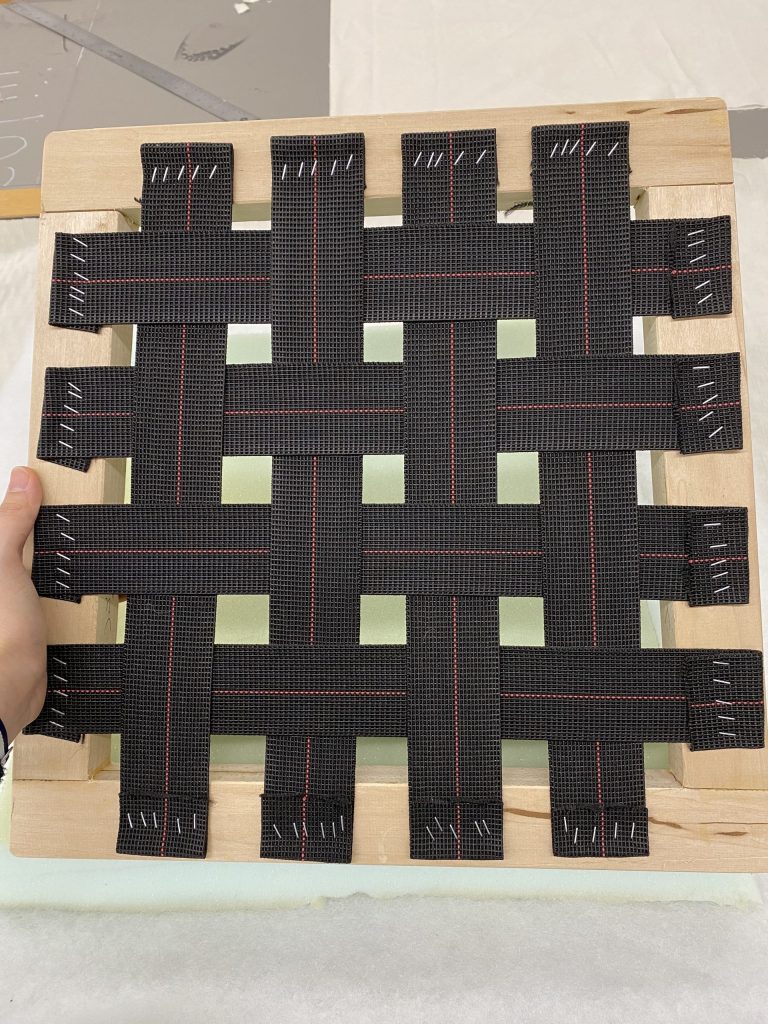

Measure your wood frame first. Get the dimension of the wood frame and arrange the elastic band evenly and regularly. It is better to leave less than 1-inch space between each strip. Mark the position on the frame with a pencil or pen.

Place the elastic band on its position, fold the edge underneath and then staple the first fold to the frame.

Tip: The edge could be unraveled sometimes, which might cause a problem to the structure. To avoid that, we could fold the edge underneath and use the staple to lock the edge.

Stretch the band by using the webbing stretcher. Press on the elastic band and feel the strength: you can feel a sense of support while the band still maintains elasticity.

Give two or three staples to fix the band on the position. Then, you can cut the band from the roll, fold the edge and staple the fold to the frame. Now, you have the first strip of the elastic band on your wood frame! Repeat the process until the whole surface is covered by parallel strips

The process is almost the same in the other direction. However, the elastic band needs to be weaved in a crisscross way.

Step two: Cut the foam and place all materials in order

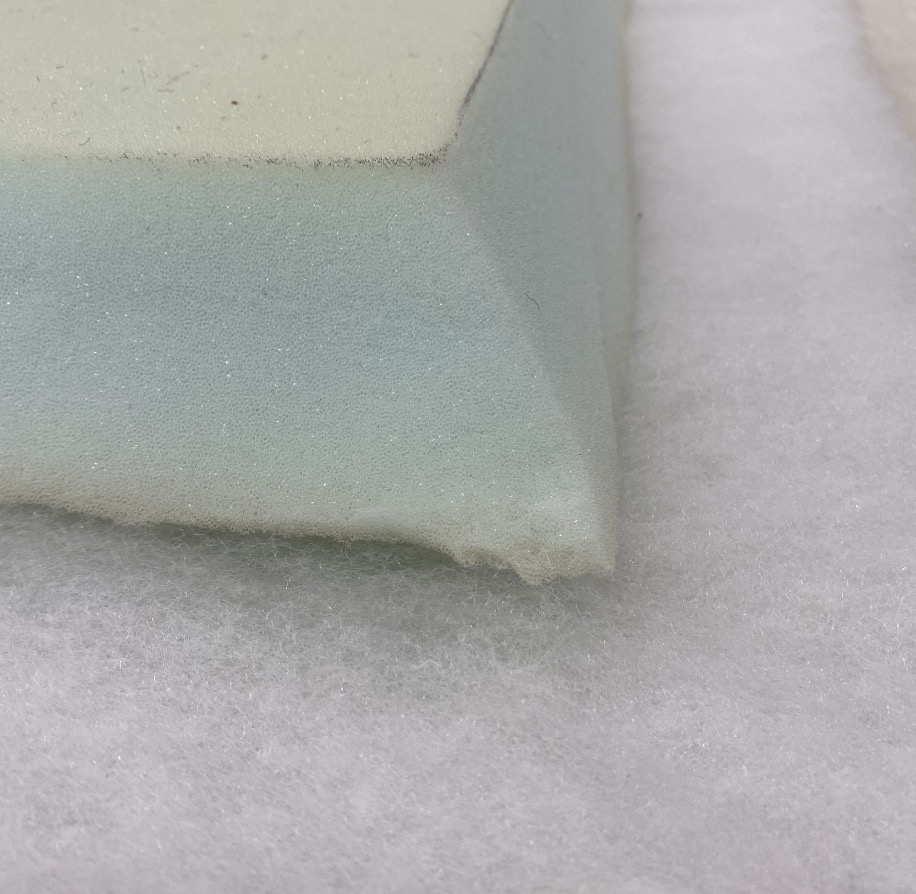

Put the wood frame on the medium density foam (the elastic band side should face to the bottom). Outline the shape with a pencil and cut the foam in 45 degree with an electric foam cutter.

Tip: Our purpose is to wrap the foam to the edge of the frame. In that case, the 45-degree cut would allow the foam to cover the frame in a more smooth and even way.

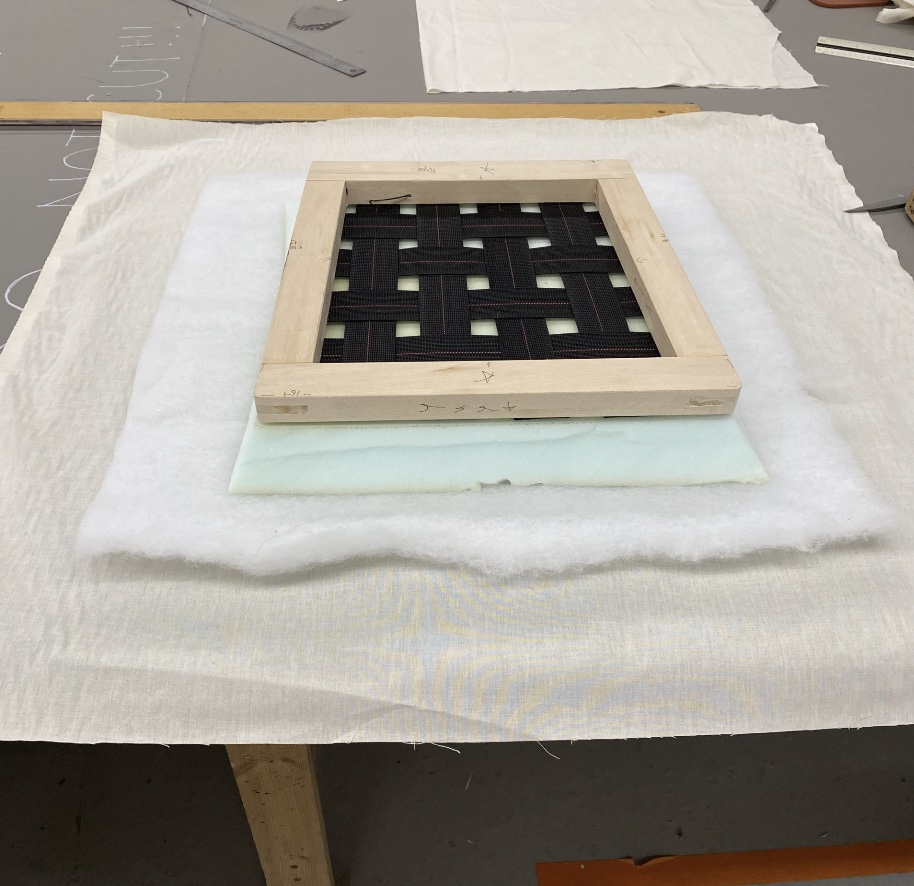

For the polyester batting, I leave about 3 inches of extra material all the way around the medium-density foam. So, the polyester batting could fully cover the foam.

After that, I cut the muslin and leave 4 inches of extra material give or take all the way around.

Thus, the order is: (top to bottom)wood frame, 2-inch thick foam, 1-inch thick polyester batting, and a piece of muslin.

Step three: Wrap and staple

This section could be divided into three steps:

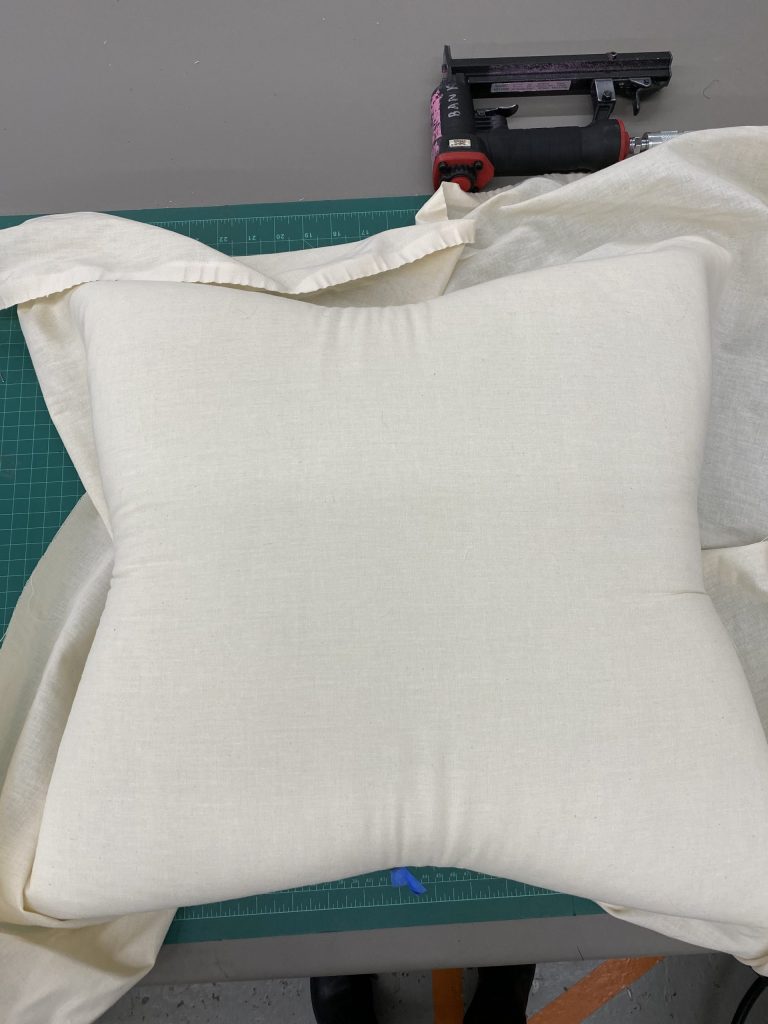

First, wrap the muslin and staple it at the middle of each wood stick.

It is kind of like setting up four basic points to fix the material on the position.

Second, make a line by following the point.

Wrap the muslin and make sure the fabric doesn’t have any fold. Then staple the muslin to the wood frame.

Third, wrap the corner.

Trim off the extra material in the corner, flatten the surface and make a nice, tidy fold.

It is quite difficult to make a beautiful fold because the muslin and polyester batting are gathered to the corner. It is better to practice several times before you staple it.

Step four: the last layer!

Select your favorite fabric, in whatever color, pattern, and texture you like. Cut the fabric and make the size a little bit larger than the muslin. Then repeat the third step.

Now you have an upholstered seat! It is quick and easy, isn’t it?

Follow Us

Guangming Street #952 MiYun, BeiJing, China

yuya.zhou13@gmail.com | HTTPS://YUYAZHOU.COM